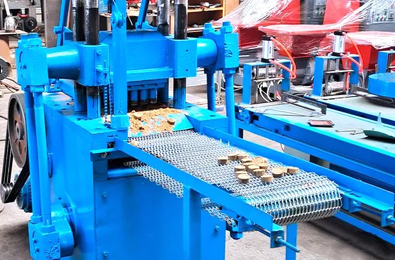

The entire hooka/ shisha charcoal briquettes production line is a efficient process from coal to coal dust or coal powder to charcoal briquettes. The charcoal production process includes crushing, mixing, briquetting, drying, and packaging. The entire production line is equipped with silo, conveyors, crusher, mixer, briquette machine, dryer which improves the degree of production automation and reduces time and labor costs.

The raw materials of the hookah/shisha charcoal briquettes making machine mainly include coal dust, charcoal powder and adhesive. Among them, coal powder is often used in the industrial field, while charcoal powder is more used in daily life, such as barbecues and heating.

Wood Charcoal: one of the common raw materials, widely available and low cost.

Coconut Shell Charcoal: has high calorific value and long burning time.

Other Plant Fiber Charcoal: such as bamboo charcoal, fruit shell charcoal, fruit tree charcoal, etc.

The common feature of these raw materials is that they have a long burning time and do not produce any pungent odor when burned, so they will not affect the taste of the hookah.

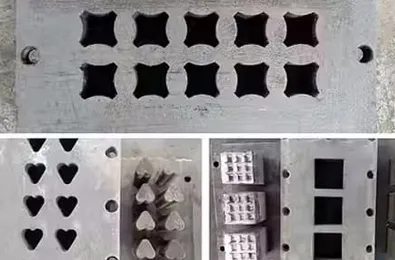

Various shapes can be customized with adjustable molding shape and size: square, circle, ring, diamond, triangle, cylinder, and other shapes optional.

1. Efficient: It can efficiently convert coal or charcoal powder into fuel charcoal briquettes.

2. Environment Friendly and Energy Saving: The charcoal briquetting reduces smoke emissions and improve the raw material utilization.

3. Easy to Operate: Charcoal powder making machine with simple structure usually adopt automated control systems, which are easy to operate.

4. Uniform Briquettes: The finished charcoal briquettes produced by this charcoal extruder machine have regular shapes and uniform density.

5. Versatile: The charcoal extruder can adjust the size, shape and density of the formed blocks according to different needs, and is suitable for various industrial and civil occasions.

6. Stable and Long Service Life.