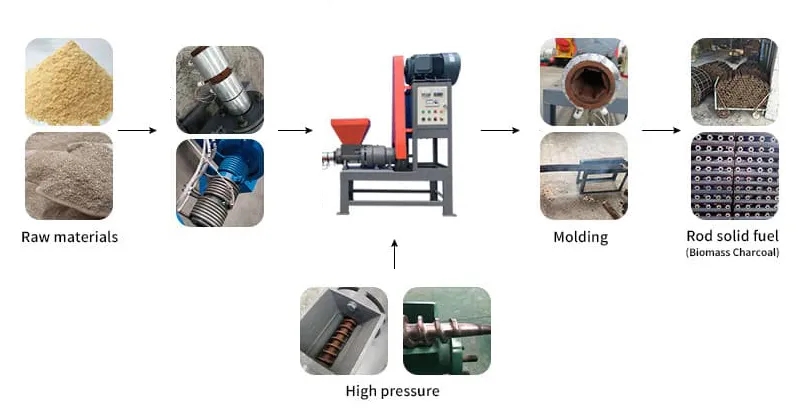

Biomass Briquette Machine

Referred to as a sawdust briquette machine, the biomass briquette equipment processes biological materials—such as wood, sawdust, peanut shells, rice husks, bagasse and other agricultural waste—into solid rod sawdust briquettes. As a practical biofuel, the product is widely used in home fireplaces, boiler heating, power plant steam generation, barbecues and other fields.

Raw Material: biological materials

Capacity: 1~30t/h