The biomass briquette production line or sawdust briquette plant has a reasonable equipment ratio connection, which can greatly reduce labor costs and improve production efficiency. It can make briquettes from biomass materials like wood waste, sawdust, rice husk, bamboo, peanut shells, cow dung, etc.

Jingxu Machinery can provide complete solution for biomass briquettes making.

Sawdust, bamboo dust, bagasse, cotton stalks, coffee husks, peanut shells, rice husks, sunflower shells, straw, sugar factory waste, coconut shell and other waste materials and residues such as castor shells, tobacco stems, tea grounds, tree bark, weeds, shrubs and branches.

Generally, the outer diameter of the finished product is 50-60mm, the hole diameter is 15-20mm, and it is in the shape of a hollow square or hexagonal cylinder. It can also be customized into spherical, granular and honeycomb shapes according to your needs and requirements.

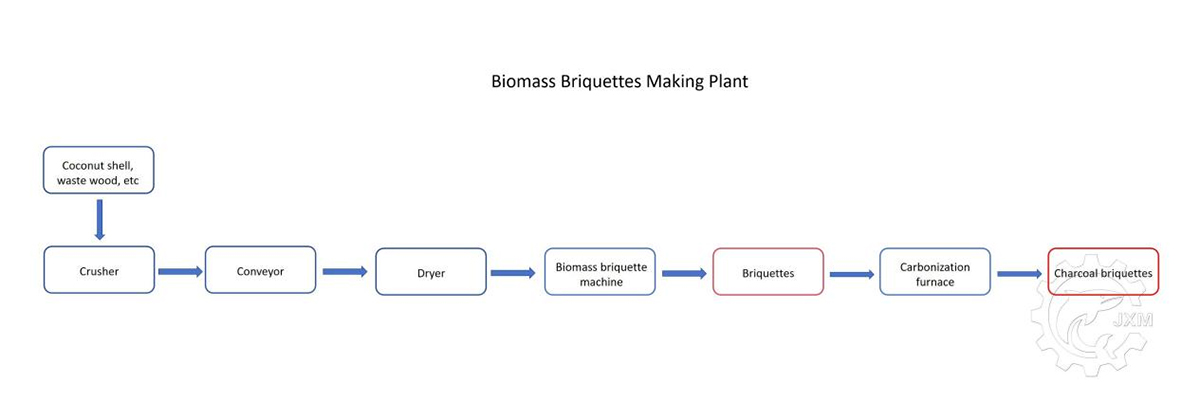

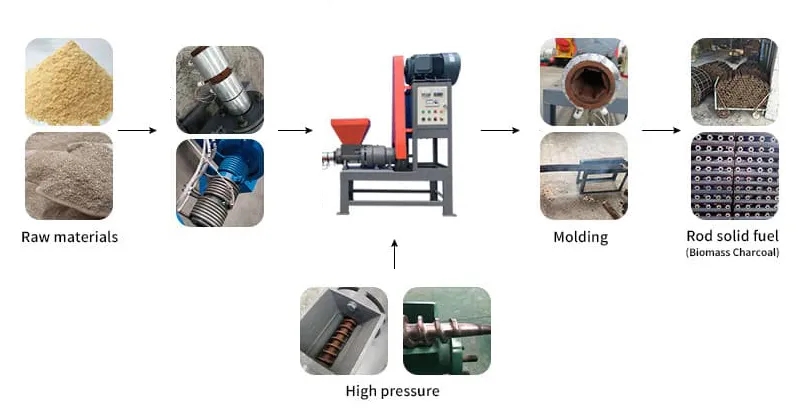

Raw Material Pretreatment: Before entering the biomass briquette machine, the raw materials usually need to be preprocessed, such as crushing and drying to ensure better shaping.

Feeding: Input the raw materials into the biomass briquette machine through the feeding port.

Pressing and Molding: A high-temperature and high-pressure zone is formed under the action of the screw propeller and the heating ring to process the loose raw materials into hollow solid rods which has high density, small size and good flammability.

1. Efficient: It can efficiently convert coal or charcoal powder into fuel charcoal briquettes.

2. Environment Friendly and Energy Saving: The charcoal briquetting reduces smoke emissions and improve the raw material utilization.

3. Easy to Operate: Charcoal powder making machine with simple structure usually adopt automated control systems, which are easy to operate.

4. Uniform Briquettes: The finished charcoal briquettes produced by this charcoal extruder machine have regular shapes and uniform density.

5. Versatile: The charcoal extruder can adjust the size, shape and density of the formed blocks according to different needs, and is suitable for various industrial and civil occasions.

6. Stable and Long Service Life.

Industrial Fuel: The charcoal briquettes produced by the charcoal briquette machine can be used as fuel for industrial boilers, drying equipment, etc., providing stable heat energy.

Daily Life: The charcoal briquettes produced by charcoal making machine are used for outdoor barbecues, household stove heating and cooking and other daily occasions. The finished briquettes have a long burning time, high heat and are easy to use.

Environmental Protection Project: The charcoal coal powder making machine can convert biomass resources such as agricultural and forestry waste into renewable energy, which has good environmental benefits.