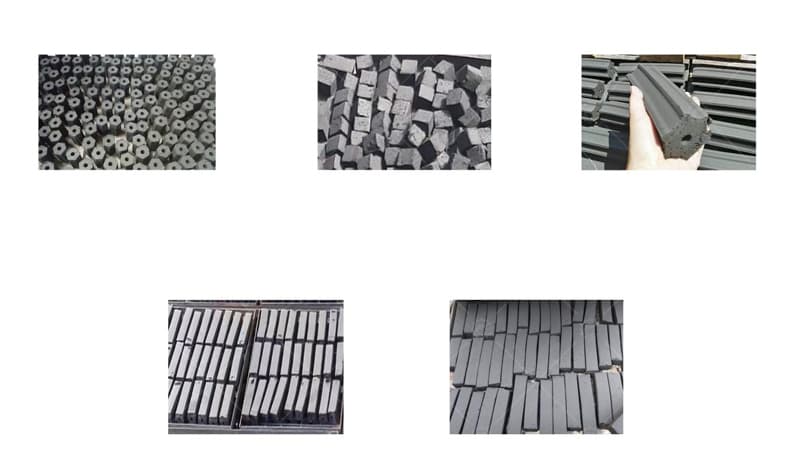

Applied Materials of Charcoal Extruder Machine

The main raw materials for charcoal making machines include coal dust, charcoal powder, and adhesive. Industrial settings commonly utilize coal dust, while charcoal powder is more frequently employed in everyday activities like barbecuing and residential heating.

Raw materials: Coal, charcoal, coke, graphite, silicon carbide, petroleum coke, etc.

Size: less than 3mm

Moisture content: The optimal moisture content for briquette production using a briquette extruder ranges from 10% to 14%. While other moisture levels are feasible for briquette making, they come with inherent drawbacks. Low moisture content increases friction during the process, resulting in slower coal output. High moisture content, on the other hand, produces softer briquettes that require longer drying time.

Adhesive: asphalt, starch, resins, sodium silicate, bentonite, plastic clay, lime and sodium, lignin, etc.