Product Application

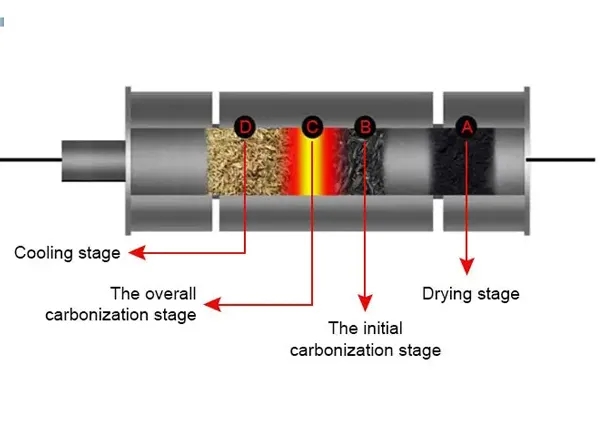

The carbonization furnace is extensively used across agriculture, industry and daily scenarios, offering solid technical backing for efficient biomass resource utilization. Meanwhile, this eco-friendly and efficient production equipment is winning favor with a growing number of processing households.

Cooking and Outdoor Daily Use: Carbonized charcoal works as fuel for barbecues, stoves and other cooking tools, while also being applicable to outdoor daily necessities.

Industrial Applications: Carbonized charcoal serves as a raw material in industrial sectors including smelting and heat treatment, and can also be utilized for activated carbon production.

Agricultural Applications: Carbonized charcoal can be used to improve soil quality, enhance soil fertility and promote crop growth.