To produce cylinder shape coal/ charcoal briquettes, you can use our coa/ charcoal briquettes making plant with charcoal extruder machine.

The raw materials for producing charcoal are very wide, and can use the resources around, such as some waste wood, coconut shell, rice shell, nut shell, etc. can be used to carbonize and then make charcoal. Therefore, charcoal production is an environmentally friendly project, and it can recycle some waste resources.

Raw material: Coal, charcoal, coke, graphite, silicon carbide, petroleum coke, etc.

Size: less than 3mm

Moisture content: 10-14 is the optimal moisture content for making briquettes on a briquette extruder. Other moisture can also be used to make briquettes, but there are also disadvantages. When the moisture is low, the friction is greater and the coal output is slow. When the moisture is high, the briquettes will be softer and the drying time will be longer.

Adhesive: asphalt, starch, resins, sodium silicate, bentonite, plastic clay, lime and sodium, lignin, etc.

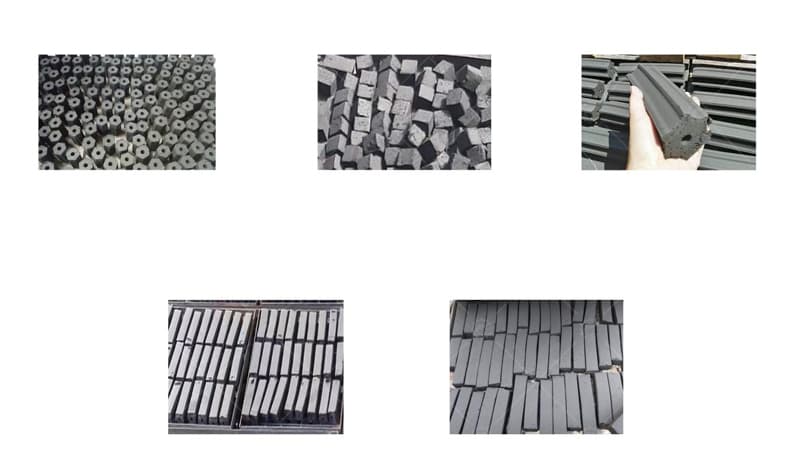

Various shapes of briquettes can be produced using molds of different shapes, with easy mold replacement and long service life. You only need one machine to produce different briquettes to meet the your needs.

Size: Common sizes of briquettes range from 20 mm to 80 mm in diameter.

Cross-sectional shape: triangle, circle, square, rectangle, plum blossom shape, etc.

The finished charcoal briquettes are energy-saving and environment-friendly, convenient for transportation, and improve the utilization rate of waste materials.

1. Fully automated production, high production efficiency;

2. Charcoal produced has high strength and a long burning time;

3. Electric box control switch, easy operation, and safer production;

4. The machine design is compact and compact and occupies a small area;