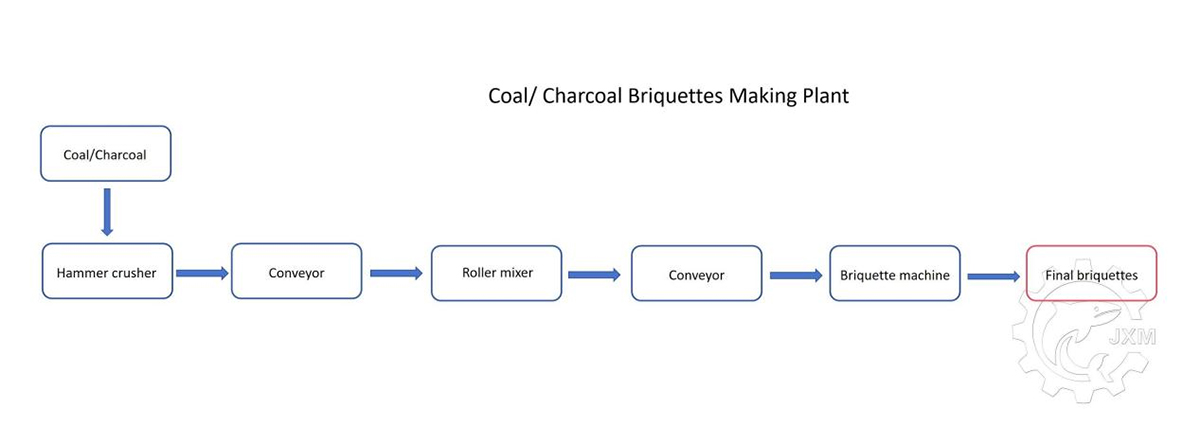

To produce coal/ charcoal briquettes, you can use our coal briquette production line( coal briquettes making plant), it is a comprehensive system transforming raw coal into high-density coal briquettes through crushing, mixing, briquetting, and drying, ensuring sustainability and cost-effectiveness in energy production. The coal briquette production line helps optimize the process to ensure efficiency and consistency, which can save time and labor.

Raw material: Coal, charcoal, coke, graphite, silicon carbide, petroleum coke, etc.

Size: less than 3mm.

Moisture content: 10-14 is the optimal moisture content for making briquettes on a briquette extruder. Other moisture can also be used to make briquettes, but there are also disadvantages. When the moisture is low, the friction is greater and the coal output is slow. When the moisture is high, the briquettes will be softer and the drying time will be longer.

Adhesive: asphalt, starch, resins, sodium silicate, bentonite, plastic clay, lime and sodium, lignin, etc.

Different shapes briquettes can be produced by using different shapes’ molds, the molds are easy to replace and have long service life. You only need one machine to produce different briquettes to meet the your needs.

Size: 20-80mm, if you have any special request, tell us directly.

The final briquettes are energy-saving and environment-friendly, convenient for transportation, and improve the utilization rate of waste materials.

| Model | Roller diameter

(mm) |

Capacity

(t/h) |

Power

(kw) |

Briquettes shape and size |

| YQ290 | 290 | 1-2.5 | 5.5-7.5 | Defined by users |

| YQ360 | 360 | 3-5 | 7.5-11 | |

| YQ430 | 430 | 5-8 | 15 | |

| YQ500 | 500 | 8-11 | 30 | |

| YQ650 | 650 | 10-15 | 37-45 | |

| YQ750 | 750 | 20-25 | 45 | |

| YQ850 | 850 | 20-28 | 55 |

Note: Other dimmension and performance can be customized