Copper Wire Granulator

Scrap copper wire granulators are capable of recycling various scrap copper wire types, delivering separated end products: copper granules and plastic particles.

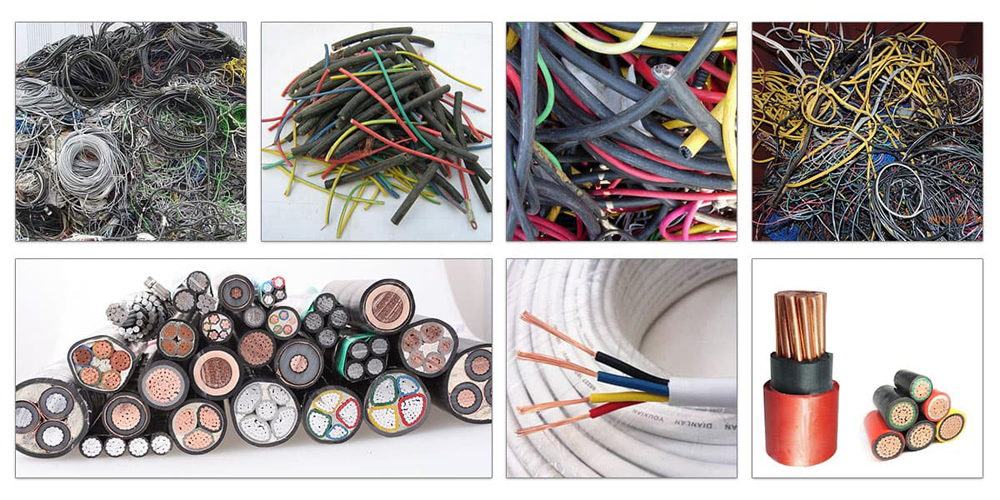

Cable Type: Communication Cable, Automotive Harness Cable,industrial cables, household cables wires, etc.

Capacity: 100-1000kg/h