Matériaux appliqués à la machine à extruder le charbon de bois

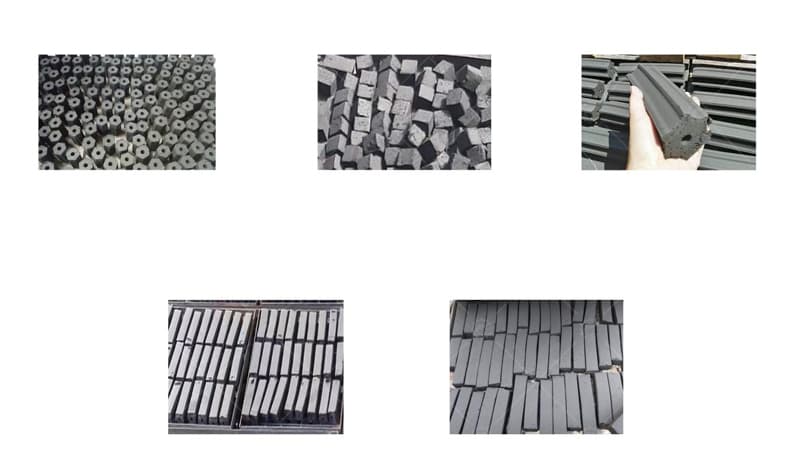

Les principales matières premières des machines à fabriquer du charbon de bois sont la poussière de charbon, la poudre de charbon de bois et l'adhésif. Les milieux industriels utilisent couramment la poussière de charbon, tandis que la poudre de charbon de bois est plus fréquemment utilisée dans les activités quotidiennes telles que les barbecues et le chauffage résidentiel. Les milieux industriels utilisent couramment la poussière de charbon, tandis que la poudre de charbon de bois est plus fréquemment utilisée dans les activités quotidiennes telles que les barbecues et le chauffage résidentiel.

Matières premières : charbon, charbon de bois, coke, graphite, carbure de silicium, coke de pétrole, etc.

Taille : moins de 3 mm

Teneur en eau : La teneur en eau optimale pour la production de briquettes à l'aide d'une extrudeuse à briquettes se situe entre 101 et 141 TTP3T. Bien que d'autres teneurs en eau soient possibles pour la fabrication de briquettes, elles présentent des inconvénients inhérents. Un faible taux d'humidité augmente les frottements au cours du processus, ce qui ralentit la production de charbon. Un taux d'humidité élevé, en revanche, produit des briquettes plus molles qui nécessitent un temps de séchage plus long.

Adhésif : asphalte, amidon, résines, silicate de sodium, bentonite, argile plastique, chaux et sodium, lignine, etc.