The Types of Shisha Charcoal Making Machine

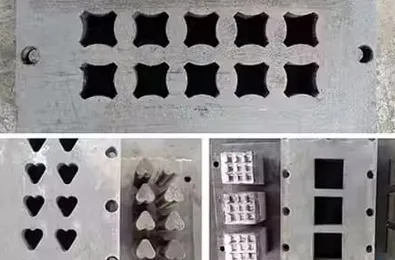

Mechanical Shisha Charcoal Making Machine: Use an automatic electronic control system to press the hookah charcoal through mechanical up and down movements. It includes the main body, motor, entrance chamber and exit conveyor belt. This machine is suitable for forming charcoal powder or powder flakes. It can press charcoal in various shapes such as round, square, convex and concave, rectangular and triangular.

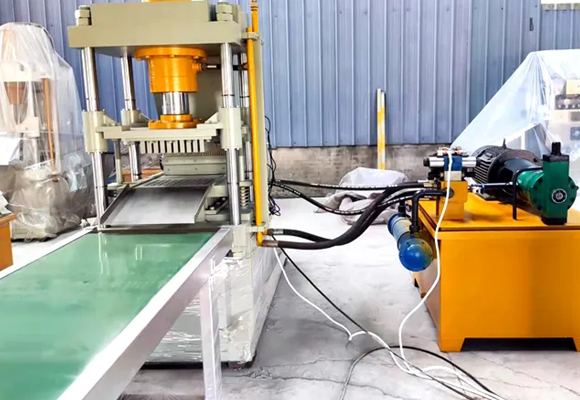

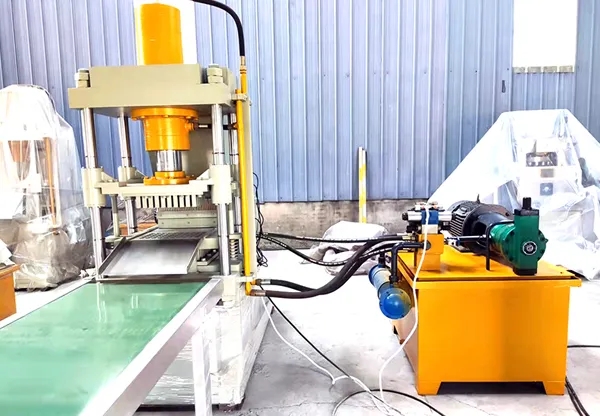

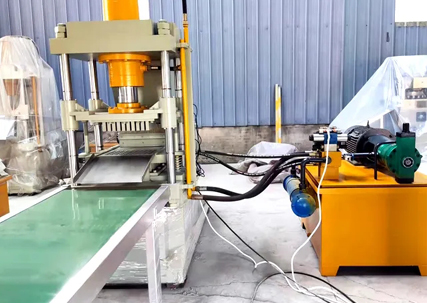

Hydraulic Shisha Charcoal Making Machine: Utilize hydraulic pressure to compress raw materials into shisha charcoals. The main structure includes the frame, hydraulic system, power distribution cabinet, mold and conveyor belt, etc. Independent temperature and power control devices, hydraulic pressure can be effectively adjusted. They offer high-pressure capabilities, ensuring tightly compacted briquettes with uniform shapes and sizes. Hydraulic shisha charcoal making machines are suitable for both small-scale and industrial production settings.

Rotary Shisha Charcoal Making Machine: Feature a rotating turret equipped with multiple punches to compress raw materials into tablet-shaped shisha charcoals. The molding mold of this machine is not pressed up and down, but rotates, which saves the waiting time for opening and closing the mold during work, so the output is large.They offer high-speed production capabilities and are suitable for large-scale manufacturing operations.