Working Process

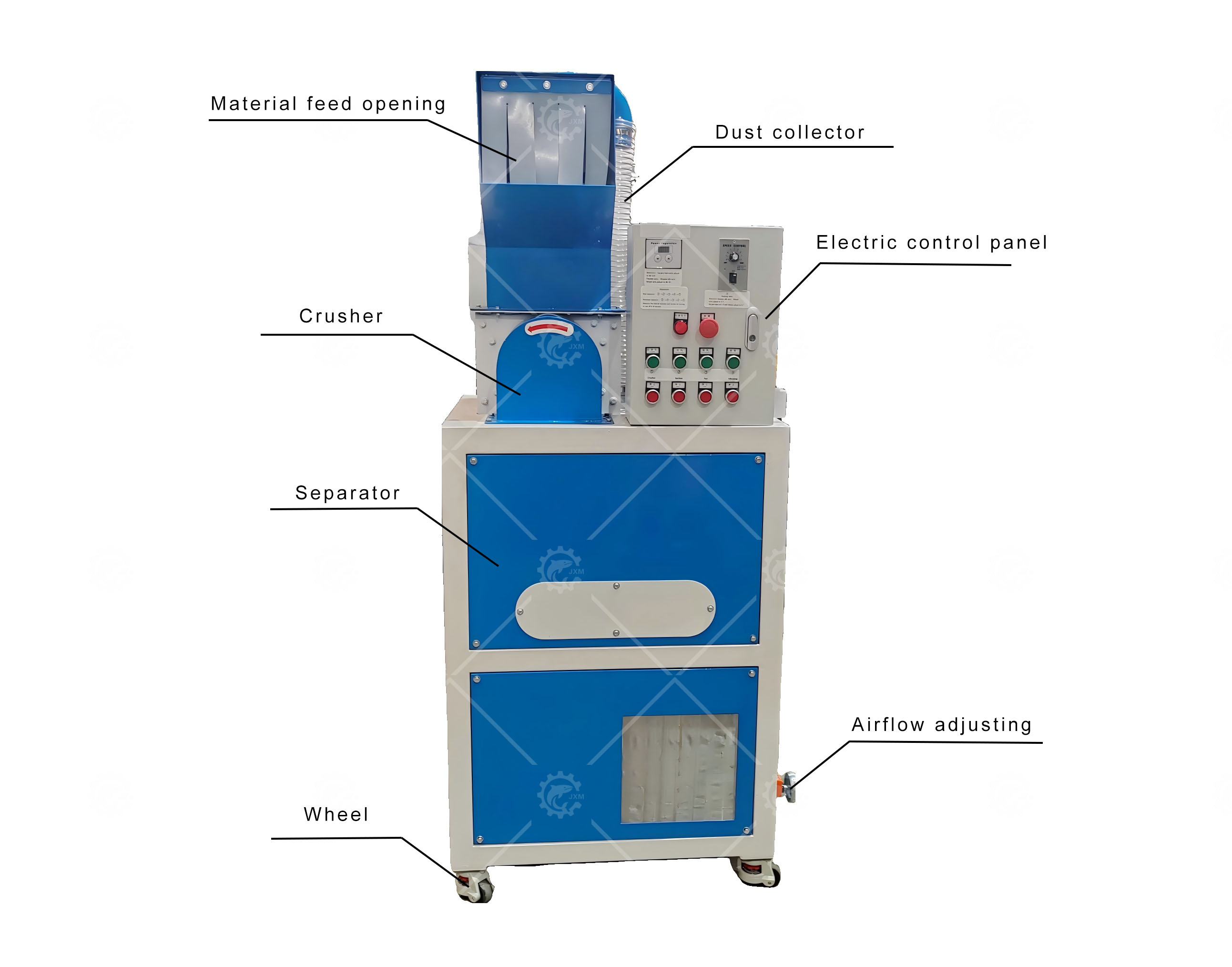

A mini copper wire granulator comprises a crusher, a separator, and a dust collection system. This equipment operates through the following steps:

Crusher: Copper wires are fed into the granulator, where the crusher component breaks them down into small fragments.

Separator: Using airflow separation methods, the finely ground copper particles are separated from the plastic insulation. The airflow carries away the lighter plastic particles, and the heavier copper particles drop into an independent collection container.

Dust collection system: The dust collection system captures and collects dust generated during the granulator’s operation.